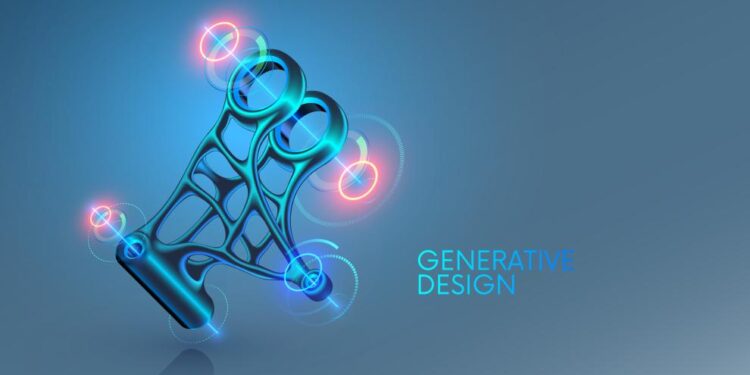

In the ever-evolving landscape of technology and design, a revolutionary force is reshaping the way we create, innovate, and engineer. This force is Generative Design, a groundbreaking approach that leverages the power of artificial intelligence (AI) to automate and optimize the design process. Unlike traditional design methods where a human painstakingly creates a model and a computer checks its feasibility, generative design flips the script. The designer defines the goals and constraints, and the AI algorithm generates hundreds, or even thousands, of potential design solutions. This paradigm shift is not just about making things faster; it’s about unlocking a level of innovation and performance that was previously unattainable.

The impact of AI-driven generative design is profound, extending far beyond simple aesthetics. It’s fundamentally changing the way industries from aerospace to automotive and consumer goods approach product development. By integrating machine learning, computational geometry, and advanced simulation, generative design software can explore a vast design space in a fraction of the time it would take a human engineer. This leads to designs that are not only more efficient and lightweight but also incredibly strong and structurally sound. This article will delve into the core concepts of generative design, explore its powerful applications across various sectors, and examine the critical role of AI in driving this transformative technology.

The Core Concepts of Generative Design

To fully appreciate the power of generative design, it’s essential to understand its foundational principles. At its heart, generative design is a computational methodology that uses algorithms to automatically generate design options based on a set of user-defined parameters. These parameters, or constraints, are the most crucial part of the process. The human designer sets the stage by specifying:

A. Performance Requirements: This includes everything from the required load-bearing capacity and stiffness to thermal performance and fluid dynamics. For instance, a designer might specify that a component must be able to withstand a certain amount of force without deforming.

B. Materials: The designer defines the materials the component can be made from. This is critical because the material properties (e.g., strength, density, elasticity) directly influence the final design. The AI algorithm will optimize the geometry based on these material characteristics.

C. Manufacturing Methods: This is a key constraint that ensures the generated design is actually producible. Generative design software can be tailored for various manufacturing processes, such as 3D printing (additive manufacturing), casting, or CNC machining. The algorithm will create a design that adheres to the limitations and capabilities of the chosen method. For example, a design for 3D printing can be far more complex and organic than one for CNC machining, which requires specific geometric clearances.

D. Design Space and Keep-Out Zones: The designer defines the maximum volume the part can occupy (the design space) and specifies areas where no material should be placed (keep-out zones). This is important for ensuring the new component fits within an existing assembly or avoids other parts.

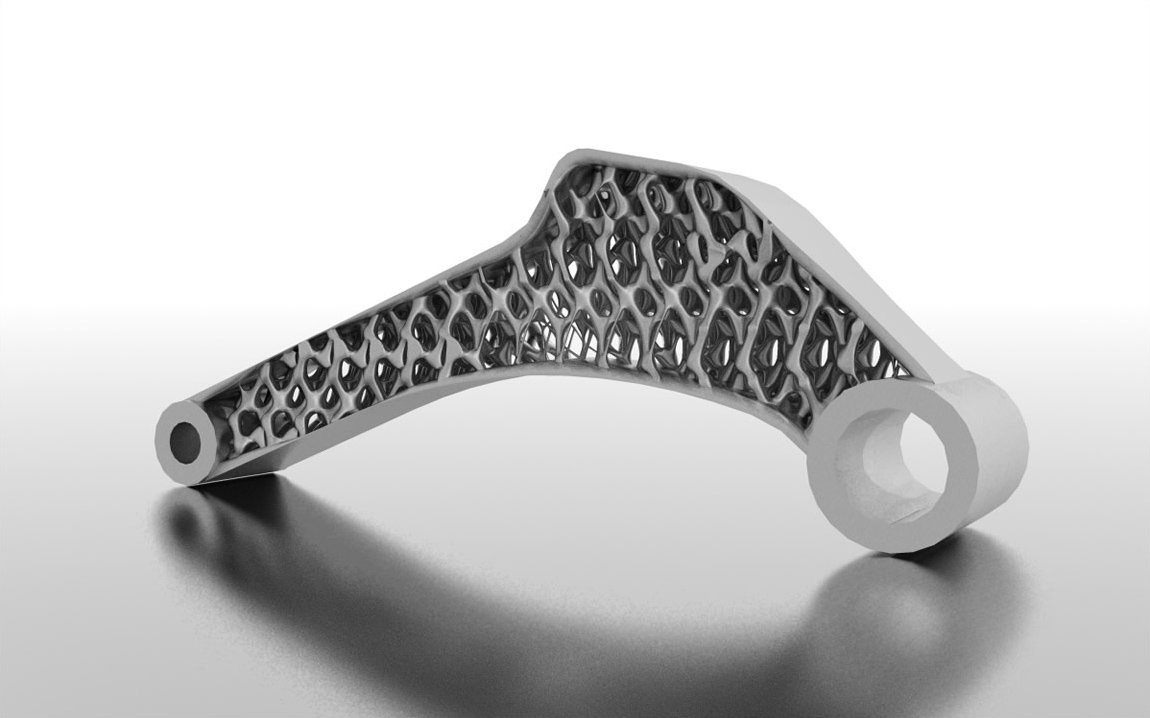

Once these parameters are defined, the generative design algorithm gets to work. It’s not simply a trial-and-error process. The AI uses sophisticated algorithms, often including Topology Optimization, to iterate through thousands of possibilities. Topology optimization is a mathematical method that optimizes material distribution within a given design space for a given set of loads and boundary conditions. The goal is to maximize the performance of the system while minimizing its weight. This process results in unique, often organic, and biomimetic structures that are incredibly efficient.

The Synergy of AI and Generative Design

The “AI” in AI Generative Design is what elevates it from a simple computational tool to a transformative technology. Machine learning algorithms play a pivotal role in several key areas:

A. Accelerated Exploration: Traditional topology optimization can be computationally intensive and time-consuming. AI, particularly machine learning models, can be trained on vast datasets of past design iterations. This allows them to quickly predict optimal material distribution and geometric shapes, drastically reducing the time required to generate a solution. Instead of starting from scratch every time, the AI has a “memory” of what works and what doesn’t.

B. Multi-Objective Optimization: Real-world engineering problems rarely have a single objective. A designer might need to balance strength, weight, cost, and thermal performance simultaneously. AI is exceptionally good at handling these complex, multi-objective optimization problems. The algorithm can generate a Pareto front of solutions, which represents the set of all non-dominated design options. This allows the designer to visualize the trade-offs between different objectives and make an informed decision. For example, the designer can see how much more weight they would have to add to achieve a certain increase in strength.

C. Learning from Data: As designers use generative design software, the AI continuously learns from the outcomes. It gathers data on the designs that are successful, the parameters that lead to optimal solutions, and the common pitfalls. This data-driven feedback loop allows the AI to become more intelligent and efficient over time, offering even better suggestions and insights for future projects. This constant learning process makes the system smarter with every use, a characteristic that no human-centric design approach can match.

D. Design for Additive Manufacturing: AI is particularly well-suited for generating designs optimized for 3D printing. Additive manufacturing removes many of the geometric constraints of traditional methods, allowing for complex, organic shapes that are impossible to produce otherwise. Generative design algorithms, guided by AI, can create intricate lattice structures, hollowed-out geometries, and bionic forms that reduce material usage and weight while maintaining or even increasing strength. The AI understands the nuances of layer-by-layer fabrication and can design accordingly.

Transforming Industries

The promise of generative design isn’t just theoretical; it’s already being implemented to solve some of the most complex engineering challenges across various industries.

A. Aerospace: In an industry where every gram of weight saved translates into significant fuel savings and increased payload capacity, generative design is a game-changer. Companies are using it to design lightweight components for aircraft, from brackets and wing parts to interior structures. For instance, a bracket designed for an aircraft cabin using generative design might be 40-50% lighter than its traditional counterpart, while being just as strong, if not stronger. The organic, skeletal shapes generated by the AI are perfectly suited for this application, offering maximum strength with minimum material.

B. Automotive: The automotive industry is in the midst of a massive transition toward electric vehicles (EVs), and generative design is playing a crucial role. Engineers are using it to design lighter chassis components, motor mounts, and battery enclosures. A lighter vehicle requires less energy to move, extending the range of an EV. Furthermore, the technology is being used to optimize heat sinks for battery packs and electronic components, ensuring efficient thermal management, which is critical for performance and longevity. The unique designs also contribute to improved crash performance by strategically distributing material to absorb impact energy.

C. Medical and Dental: The customization and precision offered by generative design are invaluable in the medical field. It is being used to create custom-fit implants, such as hip and knee replacements, that are tailored to an individual patient’s anatomy. The AI can optimize the implant’s porous structure to encourage bone growth and integration. In dentistry, generative design is used to create highly customized dental crowns and bridges that are perfectly fitted and functionally superior. The ability to design complex, patient-specific geometries with high precision is a major leap forward for personalized medicine.

D. Consumer Products: From sporting equipment to electronics, generative design is being used to create products that are both aesthetically unique and functionally superior. For example, a running shoe midsole designed with generative design could offer a unique combination of cushioning and responsiveness, optimized for the user’s specific gait. The complex lattice structures are impossible to produce with traditional methods but are a perfect fit for 3D printing. The same principle applies to products like ergonomic chairs, bike frames, and even laptop housings, where the AI can optimize for both strength and heat dissipation.

The Generative Design Workflow

The adoption of generative design requires a shift in mindset and workflow for engineers and designers. Instead of sketching an idea, the process begins by defining the problem and its parameters. The typical workflow looks like this:

A. Set Up the Problem: The designer uses a CAD (Computer-Aided Design) software interface to define the initial design space, set up constraints like forces and fixed points, and specify the desired materials and manufacturing methods. This is the crucial human-centric part of the process, where the designer’s expertise is paramount.

B. Generate Solutions: The software’s AI engine takes these inputs and begins its work. It runs multiple optimization algorithms, often in the cloud, to generate a wide array of possible solutions. This can take anywhere from minutes to hours, depending on the complexity of the problem. The user can monitor the process and see the various design options being created.

C. Explore and Refine: Once the solutions are generated, the designer uses a visualization tool to explore the results. They can filter the designs based on different criteria, such as weight, strength, and manufacturing cost. This is where the designer’s judgment and experience come into play, as they select the most promising options to move forward with.

D. Manufacture and Test: The chosen design is then prepared for manufacturing. For 3D printing, the software can automatically create the necessary support structures and generate the print file. For traditional methods, the generative design shape might serve as a starting point for further refinement or as a mold design. Finally, the physical part is produced and tested to validate its performance against the initial requirements.

Challenges and the Future of Generative Design

While generative design offers immense potential, it also presents some challenges that need to be addressed. The primary challenge is the steep learning curve for designers. The shift from direct modeling to defining parameters requires a different skill set. Furthermore, the computational power required for complex simulations can be significant, although cloud computing has helped mitigate this issue. Another challenge is the integration of generative design software with existing enterprise systems and workflows.

Looking ahead, the future of generative design is incredibly promising. We can expect to see:

A. More Accessible Tools: As the technology matures, generative design tools will become more user-friendly and integrated into mainstream CAD software, making them accessible to a wider range of designers and engineers.

B. Integration with Other Technologies: Generative design will be seamlessly integrated with other emerging technologies, such as virtual reality (VR) and augmented reality (AR), to allow for more intuitive exploration of design solutions. Imagine a designer using a VR headset to manipulate a generative design in real-time.

C. Advanced Materials and Simulation: The algorithms will evolve to handle a broader range of advanced materials, including composites and smart materials, and incorporate more complex physics simulations (e.g., fluid-structure interaction, electromagnetic properties) directly into the design process.

D. Personalized and On-Demand Manufacturing: Generative design, combined with 3D printing, will accelerate the trend of on-demand, personalized manufacturing. This could lead to a future where products are not mass-produced but are custom-designed and fabricated for individual customers at a local micro-factory.

Conclusion

The fusion of AI and generative design is not just a technological upgrade; it’s a fundamental redefinition of the creative and engineering process. It empowers designers to move beyond the limitations of their own imagination and explore a universe of possibilities, leading to solutions that are more efficient, sustainable, and innovative than ever before. The future is being designed, and AI is the architect.

Discussion about this post